Introduction

Transformer bobbins serve as essential structural components in transformers. Their significance lies in facilitating the winding of coils and insulating electrical components. This article aims to delve into the pivotal role of transformer bobbins within electrical systems, shedding light on their crucial functions and contributions.

Historical Background of Transformer Bobbins

Origins and Early Developments

2. During the late 19th and early 20th centuries, as electricity gained prominence, there emerged a need for efficient methods of transferring and controlling electrical power.

4. These early bobbins served the basic function of supporting coils and providing insulation within transformers.

5. While simple in design, these early transformer bobbins laid the groundwork for subsequent advancements in the field.

Evolution of Transformer Bobbins Over Time

2. Innovations in materials and manufacturing techniques led to the development of more durable and efficient bobbins.

3. New materials, including plastics and composites, replaced traditional wood and ceramic, offering improved performance and reliability.

4. Modern transformer bobbins are designed to withstand higher voltages and frequencies, meeting the demands of contemporary electrical systems.

5. The evolution of transformer bobbins reflects the continuous quest for enhanced efficiency and reliability in electrical engineering.

Components and Construction of Transformer Bobbins

Key Components

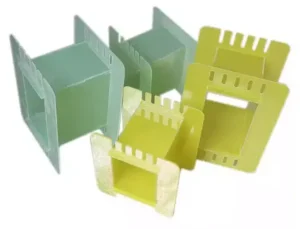

Transformer bobbins are comprised of various essential components that work together to ensure their proper functioning. These components, including the core, flanges, spools, and insulation materials, play distinct roles in the bobbin’s operation.The core, for instance, offers structural support and stability to the bobbin. Flanges, on the other hand, serve to secure the winding wire in place, facilitating the coil winding process. Spools play a crucial role in holding the wire coils and preserving their shape during operation.Moreover, insulation materials, such as paper or plastic, are integral in preventing electrical conductivity and ensuring the safety of the bobbin. These materials effectively insulate the components from each other, minimizing the risk of electrical hazards.Overall, the harmonious integration of these components is vital for the efficient and reliable performance of transformer bobbins.

Manufacturing Process

Materials Used in Transformer Bobbin Construction

- Transformer bobbins are constructed using a variety of materials, each chosen for its specific properties and characteristics.

- Common materials used in bobbin construction include plastics, such as nylon or polyester, and insulating papers.

- Plastics offer durability, heat resistance, and dimensional stability, making them ideal for high-performance applications.

- Insulating papers provide electrical insulation and thermal conductivity properties, ensuring the safety and reliability of the bobbin.

- The choice of materials depends on factors such as the intended application, environmental conditions, and cost considerations.

The Role of Transformer Bobbins in Electrical Systems

Supporting Coils and Winding

Providing Insulation and Protection

Enhancing Efficiency and Performance

Transformer bobbins contribute to the overall efficiency and performance of electrical systems.By maintaining the shape and alignment of coils, bobbins reduce the risk of coil deformation and improve electrical conductivity.This, in turn, enhances the transformer’s efficiency, reduces energy loss, and ensures consistent performance over time.

Challenges and Future Trends Of Transformer Bobbins

Common Challenges in Bobbin Design and Manufacturing

Emerging Trends and Innovations

Future Outlook for Transformer Bobbin Technology

The future prospects for transformer bobbin technology appear promising, with ongoing advancements anticipated to tackle existing challenges and stimulate innovation. Research and development endeavors will persist in enhancing material properties, refining manufacturing processes, and optimizing designs. Moreover, the integration of renewable energy systems and smart grid technologies is expected to spur demand for more efficient and adaptable transformer bobbins. Overall, transformer bobbin technology is primed for continuous growth and evolution, underscoring its pivotal role in shaping the future of electrical engineering and power distribution.