Introduction

The evolution of transformer Bobbin is inspiring. Let us understand bobbins from three directions: past, present and future.

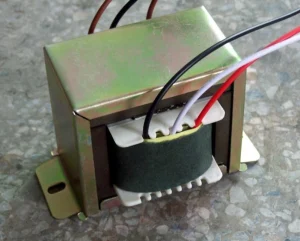

Overview of transformer bobbin technology

Importance of understanding its evolution

Purpose of the article

This article aims to comprehensively explore transformer bobbin technology, covering its historical progression, contemporary innovations, and future implications in electrical system design and manufacturing.

Early Developments in Transformer Bobbin Technology

Origins and Historical Background

Introduction of Key Innovations and Advancements

Impact on Early Transformer Designs

Early transformer bobbin technology significantly influenced transformer designs, shaping their functionality and performance. Bobbins played a crucial role in supporting coils, ensuring proper alignment and insulation, and providing structural stability. Their innovative technology enabled the creation of compact and efficient transformers, emphasizing the importance of bobbin advancements in achieving optimal performance and meeting industry demands.

Milestones in the Evolution of Transformer Bobbin Technology

Major Technological Breakthroughs and Developments

Influence of Industry Trends and Market Demands

Evolution of Materials, Manufacturing Techniques, and Design Concepts

The transition from traditional materials like paper and cardboard to modern plastics and composites has revolutionized transformer bobbin technology. With advancements in injection molding and CNC machining, precise bobbin production has become more efficient. Innovative design concepts, such as modular and customizable designs, offer greater flexibility in transformer construction. This evolution has led to more durable, thermally stable, and electrically insulated bobbin solutions, meeting diverse application needs with enhanced precision and reliability.

Modern Transformer Bobbin Technology

Current State of Transformer Bobbin Technology

Latest Innovations and Trends

Examples of cutting-edge transformer bobbin designs

This section presents a showcase of innovative transformer bobbin designs from leading manufacturers. We delve into the features and benefits of these cutting-edge designs, analyzing their impact on transformer performance. Additionally, we explore case studies that highlight the successful implementation of advanced transformer bobbin technology in real-world applications, demonstrating the practical benefits of these innovative designs.

Future Trends and Outlook

Emerging Technologies and Potential Developments

Predictions for the Future of Transformer Bobbin Technology

Implications for the Transformer Industry

The evolution of transformer bobbin technology will have significant implications for the transformer industry, driving increased competitiveness and innovation. Manufacturers will need to adapt to these changes by investing in research and development to stay ahead of the curve and meet the evolving needs of customers. Additionally, the widespread adoption of advanced bobbin technology may lead to improvements in energy efficiency and sustainability, contributing to a more environmentally-friendly future.

Conclusion

Recap of Key Points

Emphasis on the Significance of Transformer Bobbin Technology Evolution

Final Thoughts on the Importance of Staying Informed about Its Ongoing Advancements

As technology continues to evolve, it is essential for industry professionals to stay informed about the ongoing advancements in transformer bobbin technology. By keeping abreast of the latest developments, manufacturers can remain competitive, meet customer demands, and contribute to the advancement of the electrical industry as a whole. Additionally, staying informed enables stakeholders to anticipate future trends and prepare for the opportunities and challenges that lie ahead.